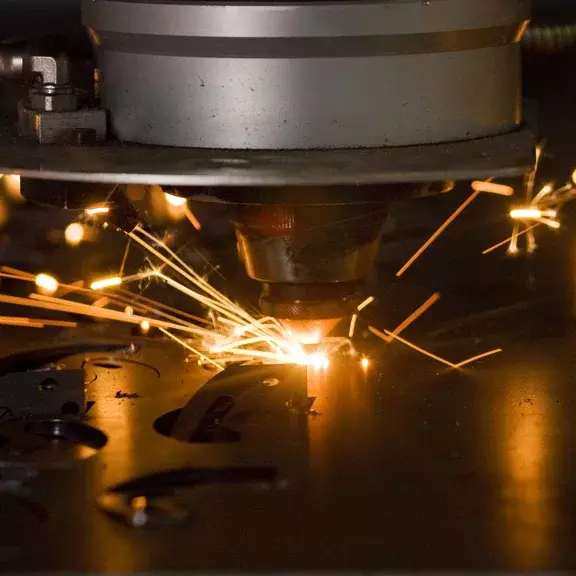

Cutting

Our solutions for laser and plasma cutting

For over 100 years, gases used for cutting have been at the core of Air Liquide's offerings. Over time, our technologies and knowledge have evolved to meet the changing needs of our customers. We continually adapt our gas solutions to meet the challenges of metal fabrication and assembly manufacturing processes.

Cutting at a glance

Cutting is used to separate pieces of sheet metal, structures and pipes. This is achieved through the use of plasma or laser cutting, where gas is an active component to melt, burn, vaporize or remove excess material, thus creating clean cut edges.

Our offer

It doesn't matter if you use plasma or laser cutting, we have the range of gases you need. Our range of industrial gases, high purity gases and mixtures can help you cut better and more efficiently.

We also have a global network of hundreds of welding and cutting specialists who help customers with programs aimed at reducing the cost of operations and optimizing quality and speed.

Cutting Applications

Plasma & Laser Cutting

In laser cutting, a laser beam is projected onto a piece to be cut and the molten metal is expelled by means of a gas jet. This process is mainly used in thin metals that require high precision and high productivity. Air Liquide provides optimized and innovative gas installations to meet your high pressure and high purity nitrogen and oxygen needs. We also supply gases and equipment to meet your flow and pressure requirements for laser gas used for CO2 lasers.

The advantages of laser cutting are: low heat inputs, minimal part distortions, no finishing process required, high quality edges, easy automation process, no tool wear, good cut quality, adaptability of automation and cuts of reduced width.

Plasma cutting is used to thermally separate metallic materials that cannot be cut by a flame. Plasma cutting allows for a smaller cutting angle compared to flame cutting, high cutting speed, clean and smooth edges, as well as high-quality welded joints. It is widely used on all types of metal to achieve quality cuts and maximize productivity. Under certain circumstances, plasma cutting can achieve a level of quality comparable to laser cutting at a considerably lower cost of production.

The advantages of using this type of cut are as follows: it does not require preheating, it reaches high temperatures that reduce cutting time, and the equipment is lighter than mechanical cutting processes.

Related equipment:

- Welding machines

- Welding guns

- Welding and cutting torches

- Consumables

- Gas welding and cutting equipment

- Gas hoses

Oxy-cutting

OFC cutting is a highly efficient cutting method achieved through a chemical reaction at high temperatures. To achieve the right conditions to perform a cut by this method, it is necessary to have a source of high purity oxygen that can supply it for long periods of time. Our solution for cutting with our mixture of oxygen and acetylene consists of a flame created by oxy-fuel. The great flexibility of this process combined with its excellent cutting performance makes it ideal for manual and automatic applications, for use in metal fabrication, shipbuilding yards, burners, scrap metal, etc.

Related equipment:

- Welding machines

- Welding guns

- Welding and cutting torches

- Consumables

- Gas welding and cutting equipment

- Gas hoses

Our gases

Related Industries

Resources

Why choose us

-

Industry Leader

We are a world leader in gases, technologies and services for Industry and Health.

-

Expertise

We have a global network of experts available to help you develop solutions that meet your specifications and challenges.

-

Extensive infrastructure network

We own and operate several gas production and filling facilities

-

Reliability

Our solutions are reliable, reproducible and comply with strict and constantly evolving regulations.

-

Focused on quality

We strive for absolute quality control of processes and products, and our products meet and exceed industry standards.

-

One-Stop Solution Provider

We offer a full range of products in various purities and modes of supply and a range of services to meet your specific needs.

-

Sustainability

With a strong commitment to climate change and the energy transition, our solutions are developed to achieve the highest performance in your applications and reduce your environmental impact.

What is right for me?

Modes of Supply

Learn about the different types of supply modes we offer.

What can we do for you?

Applications

Discover how we can assist you in your applications.